Bronze alloys properties

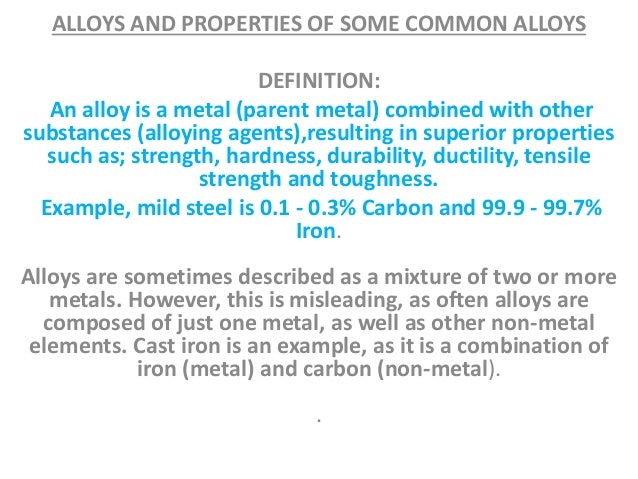

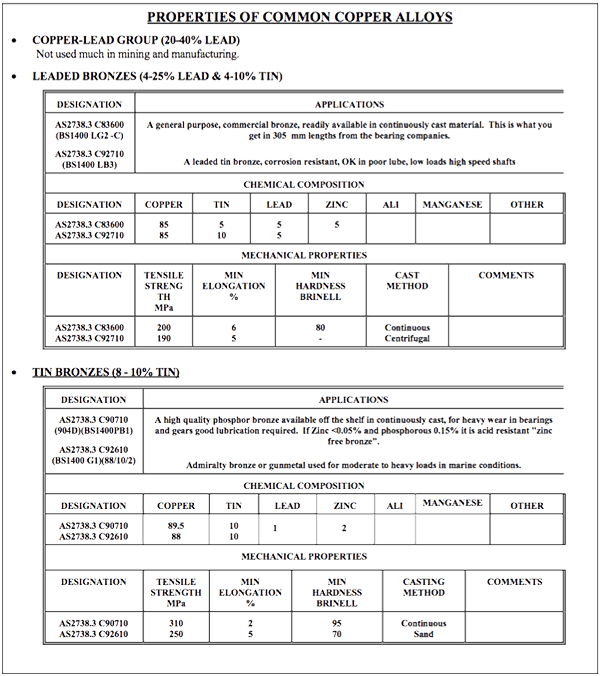

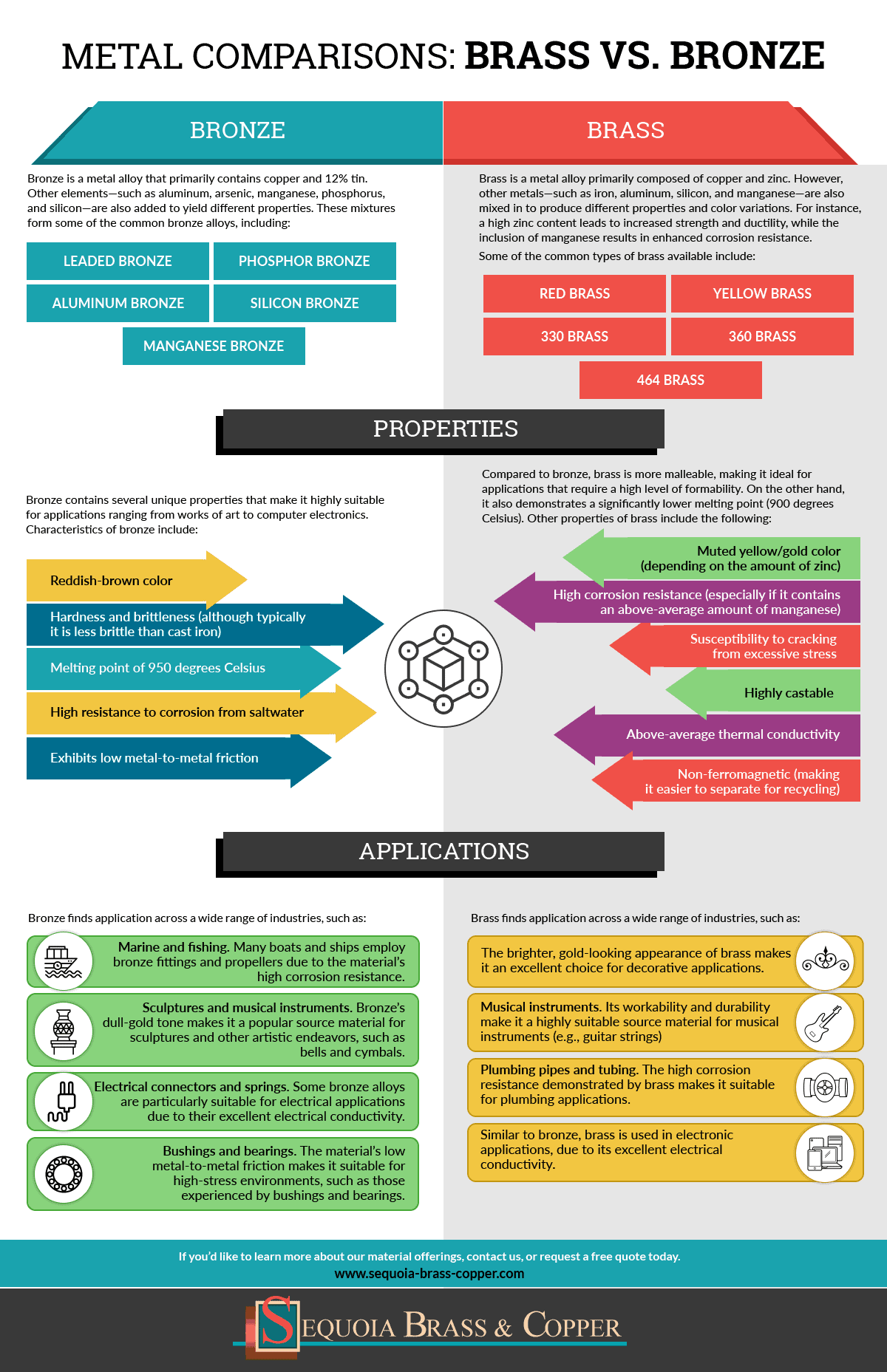

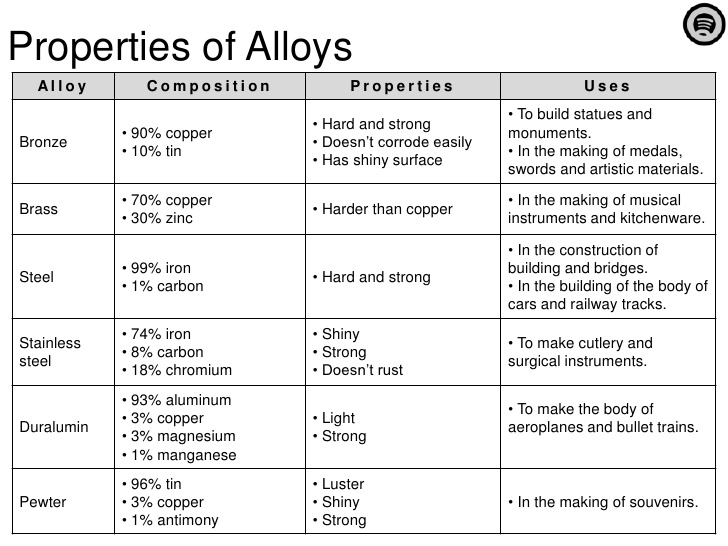

Bronze Alloys Properties. For sculpture casting this is desirable as it helps to fill a mold. Aluminium bronzes are alloys of copper and aluminium. Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. Bearing bronze alloys are for general utility bearings and bushings and which are highly resistant to impact wear and corrosion.

All About Bearing Bronze Strength Properties And Uses From thomasnet.com

All About Bearing Bronze Strength Properties And Uses From thomasnet.com

Iron nickel manganese and silicon are sometimes added. For sculpture casting this is desirable as it helps to fill a mold. Aluminum bronze bearings are used in heavily loaded applications. Aluminium bronzes are alloys of copper and aluminium. Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. Bearing bronze alloys are general purpose bearing alloy possessing good anti friction properties ample strength and hardness adequate ductility and excellent machinability.

For sculpture casting this is desirable as it helps to fill a mold.

Trace amounts of other metals such as aluminum manganese phosphorus and silicon may also be present in the alloy. Bearing bronze alloys are for general utility bearings and bushings and which are highly resistant to impact wear and corrosion. Alloy nes833 is an aluminium bronze with good ductility and impact strength. 10 20 zn alloys are known as gilding metals that are used in the jewellery industry and in the production of heat exchangers. It also has superior corrosion resistance. The upper threshold of zinc in formable brass is around 35.

Source: slideshare.net

Source: slideshare.net

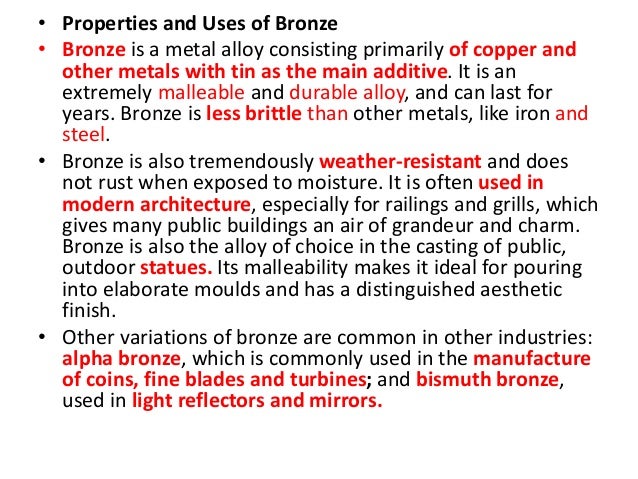

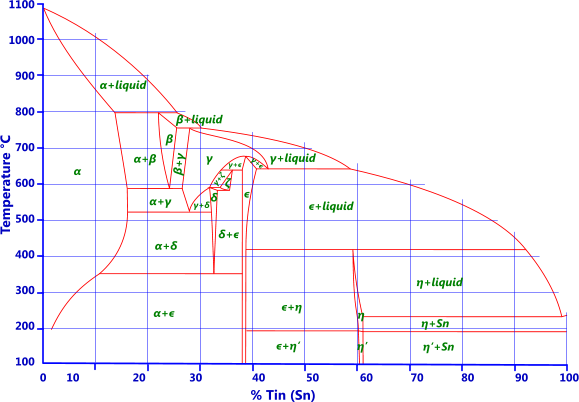

Bronze is an alloy consisting primarily of copper commonly with about 12 12 5 tin and often with the addition of other metals such as aluminium manganese nickel or zinc and sometimes non metals or metalloids such as arsenic phosphorus or silicon these additions produce a range of alloys that may be harder than copper alone or have other useful properties such as strength ductility. Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. It is also harder than pure iron and far more resistant to corrosion. They are best known for their high corrosion and oxidation resistance combined with exceptionally good mechanical properties. It also has superior corrosion resistance.

Source: thoughtco.com

Source: thoughtco.com

Bronze exhibits low friction against other metals. Bronze is harder than copper as a result of alloying that metal with tin or other metals. Trace amounts of other metals such as aluminum manganese phosphorus and silicon may also be present in the alloy. For sculpture casting this is desirable as it helps to fill a mold. It is also harder than pure iron and far more resistant to corrosion.

Source: slideshare.net

Source: slideshare.net

Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. Bronze is a copper based alloy that typically consists of approximately 88 copper and 12 tin. The upper threshold of zinc in formable brass is around 35. They are best known for their high corrosion and oxidation resistance combined with exceptionally good mechanical properties. 10 20 zn alloys are known as gilding metals that are used in the jewellery industry and in the production of heat exchangers.

Source: matweb.com

Source: matweb.com

It is also harder than pure iron and far more resistant to corrosion. A bronze is an alloy of copper and other metals most often tin but also aluminium and silicon. Bronze is a copper based alloy that typically consists of approximately 88 copper and 12 tin. Aluminium bronzes are alloys of copper and aluminium. The properties applications and fabrication details are provided for bronze alloy nes833.

Source: thomasnet.com

Source: thomasnet.com

Brittle but less so than cast iron. Bronze exhibits low friction against other metals. 30 zn alloys are called cartridge brass for a pretty self explanatory reason. Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. The content of aluminium ranges mostly between 5 and 11.

Source: slideshare.net

Source: slideshare.net

Bronze is an alloy consisting primarily of copper commonly with about 12 12 5 tin and often with the addition of other metals such as aluminium manganese nickel or zinc and sometimes non metals or metalloids such as arsenic phosphorus or silicon these additions produce a range of alloys that may be harder than copper alone or have other useful properties such as strength ductility. Iron nickel manganese and silicon are sometimes added. Aluminum bronze bearings are used in heavily loaded applications. Adding other alloying elements can further improve brass s properties. Bronze is also more fusible i e more readily melted and is hence easier to cast.

Source: thomasnet.com

Source: thomasnet.com

Aluminum bronzes and nickel aluminum bronzes contain between 3 and 12 aluminum which strengthens the alloy. The properties applications and fabrication details are provided for bronze alloy nes833. Many bronze alloys display the unusual property of expanding a small amount when solidifying from a liquid into a solid. 10 20 zn alloys are known as gilding metals that are used in the jewellery industry and in the production of heat exchangers. Bronze exhibits low friction against other metals.

Source: accendoreliability.com

Source: accendoreliability.com

Bronze is an alloy consisting primarily of copper commonly with about 12 12 5 tin and often with the addition of other metals such as aluminium manganese nickel or zinc and sometimes non metals or metalloids such as arsenic phosphorus or silicon these additions produce a range of alloys that may be harder than copper alone or have other useful properties such as strength ductility. They are best known for their high corrosion and oxidation resistance combined with exceptionally good mechanical properties. Bronze is an alloy consisting primarily of copper commonly with about 12 12 5 tin and often with the addition of other metals such as aluminium manganese nickel or zinc and sometimes non metals or metalloids such as arsenic phosphorus or silicon these additions produce a range of alloys that may be harder than copper alone or have other useful properties such as strength ductility. For sculpture casting this is desirable as it helps to fill a mold. Bronze is a copper based alloy that typically consists of approximately 88 copper and 12 tin.

Source: thoughtco.com

Source: thoughtco.com

For sculpture casting this is desirable as it helps to fill a mold. Trace amounts of other metals such as aluminum manganese phosphorus and silicon may also be present in the alloy. It also has superior corrosion resistance. The upper threshold of zinc in formable brass is around 35. Upon exposure to air bronze oxidizes but only on its outer layer.

Source: thomasnet.com

Source: thomasnet.com

Iron nickel manganese and silicon are sometimes added. Adding other alloying elements can further improve brass s properties. The content of aluminium ranges mostly between 5 and 11. 10 20 zn alloys are known as gilding metals that are used in the jewellery industry and in the production of heat exchangers. Bearing bronze alloys are general purpose bearing alloy possessing good anti friction properties ample strength and hardness adequate ductility and excellent machinability.

Source: pt.slideshare.net

Source: pt.slideshare.net

Upon exposure to air bronze oxidizes but only on its outer layer. 30 zn alloys are called cartridge brass for a pretty self explanatory reason. The content of aluminium ranges mostly between 5 and 11. Bearing bronze alloys are general purpose bearing alloy possessing good anti friction properties ample strength and hardness adequate ductility and excellent machinability. Brittle but less so than cast iron.

Source: calqlata.com

Source: calqlata.com

30 zn alloys are called cartridge brass for a pretty self explanatory reason. The properties applications and fabrication details are provided for bronze alloy nes833. Bronze is an alloy consisting primarily of copper commonly with about 12 12 5 tin and often with the addition of other metals such as aluminium manganese nickel or zinc and sometimes non metals or metalloids such as arsenic phosphorus or silicon these additions produce a range of alloys that may be harder than copper alone or have other useful properties such as strength ductility. It also has superior corrosion resistance. Upon exposure to air bronze oxidizes but only on its outer layer.

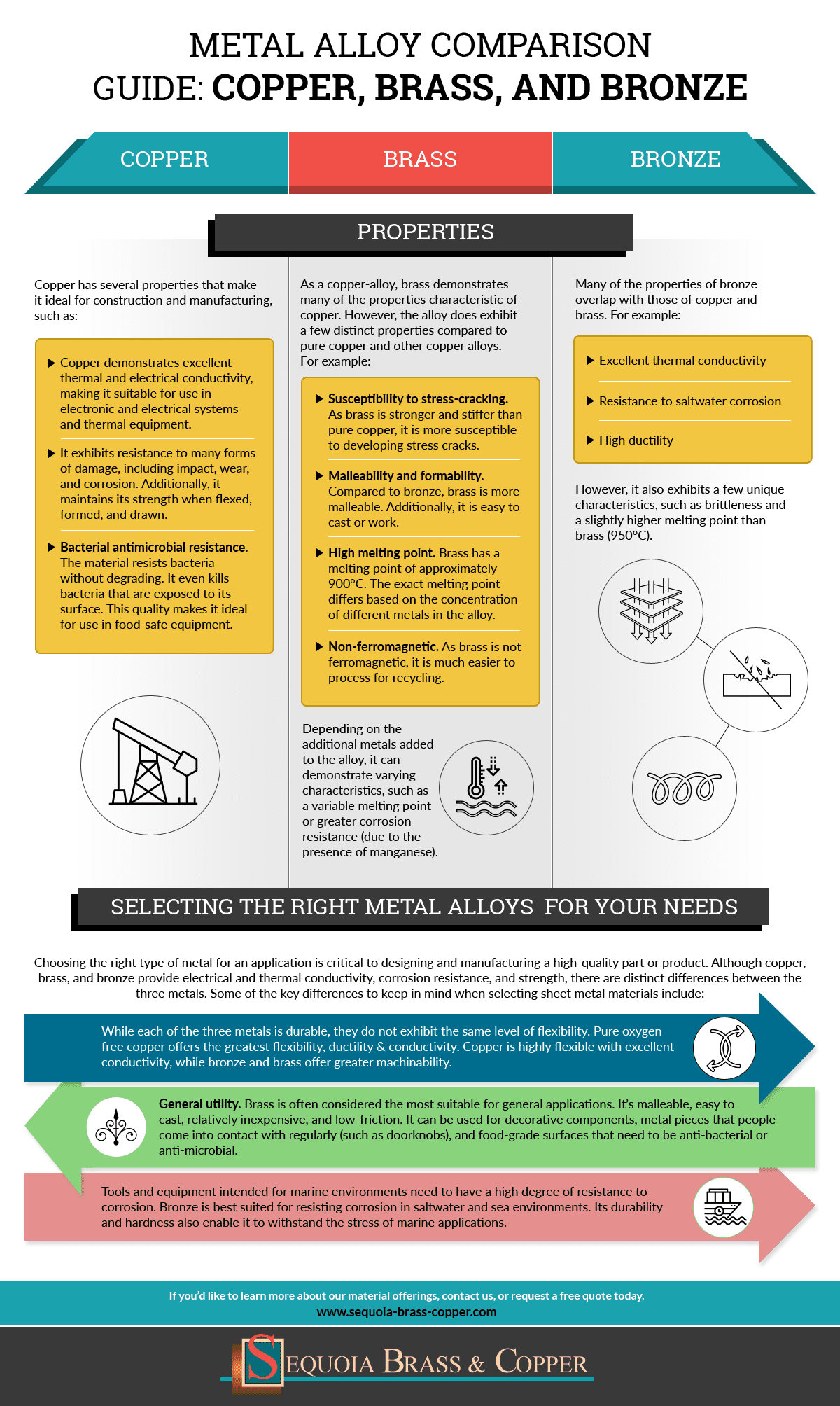

Source: sequoia-brass-copper.com

Source: sequoia-brass-copper.com

Trace amounts of other metals such as aluminum manganese phosphorus and silicon may also be present in the alloy. Brittle but less so than cast iron. They are best known for their high corrosion and oxidation resistance combined with exceptionally good mechanical properties. Adding other alloying elements can further improve brass s properties. Bronze is also more fusible i e more readily melted and is hence easier to cast.

Source: richkosh.blogspot.com

Source: richkosh.blogspot.com

Brittle but less so than cast iron. Iron nickel manganese and silicon are sometimes added. Many bronze alloys display the unusual property of expanding a small amount when solidifying from a liquid into a solid. The properties applications and fabrication details are provided for bronze alloy nes833. Aluminum bronze bearings are used in heavily loaded applications.

Source: sequoia-brass-copper.com

Source: sequoia-brass-copper.com

Brittle but less so than cast iron. Trace amounts of other metals such as aluminum manganese phosphorus and silicon may also be present in the alloy. It is also harder than pure iron and far more resistant to corrosion. The upper threshold of zinc in formable brass is around 35. Bronze exhibits low friction against other metals.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title bronze alloys properties by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.